3D Modeling & CAD/CAM Services

CNC Toolpath provides services for creating precision engineered digital models, detailed solid models, assemblies, and technical drawings using advanced CAD software optimized for CNC manufacturing. Additionally, we provide CAM services, translating CAD designs into instructions for manufacturing machines, such as CNC machines and 3D printers.

Our Comprehensive Design and Manufacturing Solutions

CNC Toolpath offers a full suite of 3D Modeling, CAD, and CAM services designed to support your manufacturing workflow from initial concept or existing data through the machine ready code and quality verification. Our expert 3D Modeling & CAD/CAM services address these challenges directly. We provide the specialized skills needed to create precise digital designs and generate optimized, error-free machine programs. We collaborate closely with you to understand your specific requirements and deliver tailored solutions that integrate seamlessly with your operations.

CNC Toolpath Approach

CNC Toolpath offers remote access to expert 3D modeling, CAD, and CAM professionals, offering significant advantages for manufacturers. We offer part design solutions tailored for manufacturing. We create detailed and accurate engineering drawings, including dimensions, tolerances, material specifications, and GDT, to ensure seamless production and quality control.

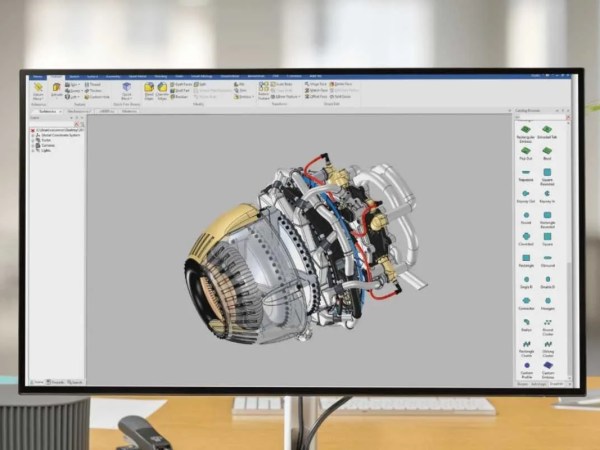

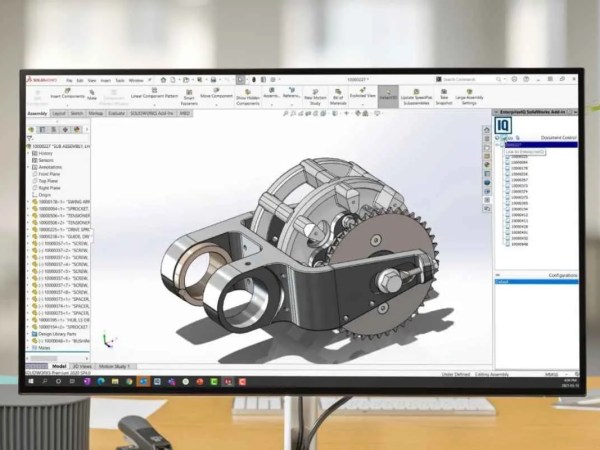

We use the advanced CAD software optimized for CNC manufacturing, and other software includes CATIA V5, Mastercam, SolidWorks, Fusion 360, PowerMill, and Inventor.

Our 3D Modeling & CAD/CAM Services

CNC Toolpath provides remote CNC programming services to ensure you get accurate, efficient, and machine-specific programming from skilled programmers. We are proficient in complex multi-axis CNC programming to meet diverse manufacturing requirements, from simple components to highly complex parts. We deliver production-ready programs tailored to specific requirements, such as precision tool paths, complex surface machining, or multi-axis optimization, to ensure smooth operations and minimal cycle times.

3D Modeling Services

3D Modeling involves creating digital three dimensional representations of objects that are very important for visualizing designs developing concepts and providing the foundational geometry needed for subsequent engineering and manufacturing processes.

Our 3D Modeling services focus on creating digital models and assemblies that are ready for CNC manufacturing.

We provide functionalities such as 2D to 3D conversion and creating detailed solid models and assemblies using advanced software. This ensures your designs are accurate manufacturable and ready for the next steps in the CAD/CAM process .

CAD Services

CAD (Computer Aided Design) services focus on creating detailed 2D and 3D technical designs, including blueprints layouts and comprehensive technical documentation. CAD is used in various engineering and product design applications emphasizing precision technical accuracy and manufacturing specifications.

CNC Toolpaths CAD services offer solutions for creating modifying and documenting designs using advanced software We provide services for creating detailed 2D drawings and 3D models complete with precise dimensions tolerances and GDT. Our expertise streamlines your design process improves accuracy and enhances collaboration leading to increased efficiency and cost reduction in manufacturing.

CAM Services

CAM (Computer Aided Manufacturing) services involve using software to translate CAD designs into instructions for manufacturing machines such as CNC machines. This includes generating toolpaths and automating manufacturing processes like machining laser cutting and 3D printing. CNC Toolpath team specialize in generating precise toolpaths and machinespecific G-code from the CAD designs.

We utilize advanced CAM software to optimize tool movements reduce machining time and ensure seamless production. Our focus on detail and efficiency directly addresses pain points related to slow production tool wear and inconsistent output by delivering robust productionready programs.

Engineering Drawings

CNC Toolpath provides expert engineering services for creating detailed and accurate engineering drawings tailored for manufacturing and machining. Detailed and accurate engineering drawings are a critical output from the design phase providing all necessary information for manufacturing machining and fabrication.

Our precision engineered technical drawings include all critical information like dimensions tolerances material specifications and GDT to ensure seamless production and quality control. We deliver precise drawings with professional industrystandard documentation for applications such as CNC machining prototyping and assembly.

The CNC Toolpath Advantage

We offer part design solutions tailored for manufacturing, focusing on efficient manufacturing, material optimization, and cost-effective solutions. Furthermore, we also create detailed and accurate engineering drawings, including dimensions, tolerances, material specifications, and GDT, to ensure seamless production and quality control.

Tools and Technology We Use

We are working with manufacturing businesses for creating precision engineered digital models, developing detailed solid models, creating assemblies, and generating technical drawings.

Providing part design solutions tailored for manufacturing and CNC machining, concept development, CAD modeling, and design optimization. Creating engineering drawings.

Advanced tools use such as CAD software optimized for CNC manufacturing and other software includes CATIA V5, Mastercam, SolidWorks, Fusion 360, PowerMill, and Inventor.