CNC Engraving and Artistic Machining Solutions

CNC Toolpath offers professional CNC engraving services, including creating artistic carvings industrial markings and decorative engravings. We are proficient in producing intricate designs on diverse materials such as wood, metal, and stone using Aspire and ArtCAM softwares. We also offer precision CNC programming and CAD/CAM services in multi-axis CNC milling, lathe programming, toolpath optimization, and post processor development and customizations.

CNC Engraving Services

CNC engraving can be executed through various techniques, each suited for different materials and desired outcomes. We work with modern CNC engraving, which utilizes computer-controlled machinery to cut or mark designs into surfaces such as metal and plastic. This process is capable of very sophisticated results. Our CNC engraving and artistic machining services are backed by our extensive knowledge in CNC Programming for 3D Modeling, CAD Designing, NC Validation, and CNC Toolpath Optimization, which ensures that your manufacturing needs are met in a seamless manner. Let CNC Toolpath apply our expertise to your engraving projects, whether you need precise industrial markings or complex artistic expression.

Our CNC Engraving and Artistic Machining Services

#1 Industrial markings, such as adding essential information directly onto parts such as serial numbers, part numbers, logos, text, or QR codes for traceability and identification

#2 Decorative Artistic Engraving by creating artistic carvings and aesthetic patterns such as intricate designs on components or surfaces such as those seen in artistic machining techniques like Guilloche Rose Engines, Jeweling, and Engine Turning.

#3 Branding applies such as logos or other branding elements to products or components for identity and recognition.

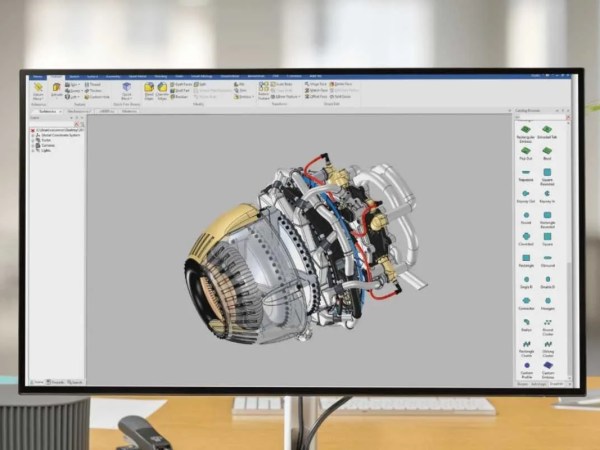

Our 3D Modeling & CAD/CAM Services

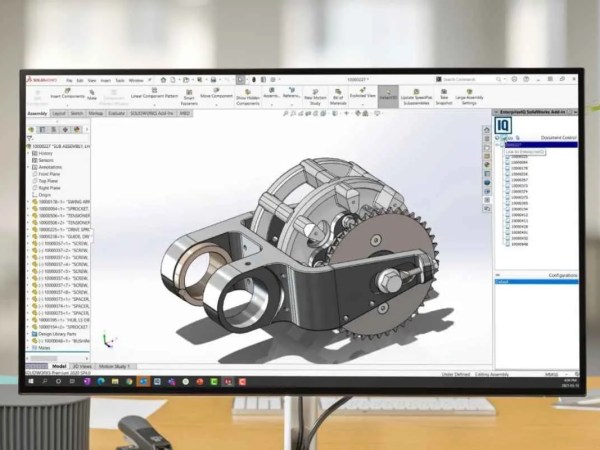

CNC Toolpath provides remote CNC programming services to ensure you get accurate, efficient, and machine-specific programming from skilled programmers. We are proficient in complex multi-axis CNC programming to meet diverse manufacturing requirements, from simple components to highly complex parts. We deliver production-ready programs tailored to specific requirements, such as precision tool paths, complex surface machining, or multi-axis optimization, to ensure smooth operations and minimal cycle times.

Mill and Mini CNC Engraving

Most CNC milling machines can be employed for engraving. This method typically uses rotating tools like V-bits, small Ballnose, End Mills, and drag engravers. An engraving end mill is frequently used with CNC mills during part production. Because engraving tools typically have small diameters, achieving optimal results often benefits from a high-speed spindle. For surfaces that are not perfectly flat, floating tool holders can be used to compensate.

Laser Engraving

CAD (Computer Aided Design) services focus on creating detailed 2D and 3D technical designs, including blueprints layouts and comprehensive technical documentation. CAD is used in various engineering and product design applications emphasizing precision technical accuracy and manufacturing specifications.

CNC Toolpaths CAD services offer solutions for creating modifying and documenting designs using advanced software We provide services for creating detailed 2D drawings and 3D models complete with precise dimensions tolerances and GDT. Our expertise streamlines your design process improves accuracy and enhances collaboration leading to increased efficiency and cost reduction in manufacturing.

CAM Services

CAM (Computer Aided Manufacturing) services involve using software to translate CAD designs into instructions for manufacturing machines such as CNC machines. This includes generating toolpaths and automating manufacturing processes like machining laser cutting and 3D printing. CNC Toolpath team specialize in generating precise toolpaths and machinespecific G-code from the CAD designs.

We utilize advanced CAM software to optimize tool movements reduce machining time and ensure seamless production. Our focus on detail and efficiency directly addresses pain points related to slow production tool wear and inconsistent output by delivering robust productionready programs.