Custom CNC Programming & Optimization

CNC Toolpath offers expert CNC programming for complex multi-axis operations, including 3,4, and 5-axis milling and lathe machines. These programs are designed for high precision efficiency, superior surface finishes, error reduction, and material usage optimization.

Our Comprehensive CNC Programming Solutions

Our precision CNC programming services are designed for businesses in industries requiring high accuracy and complex part production. This includes aerospace, automotive, and mold manufacturing. We are also well-suited for generating precision parts for sectors like R&D and medical. Whether you need programming for simple 3-axis parts or intricate 5-axis components, we have the expertise to handle projects of any size or complexity.

CNC Toolpath Process

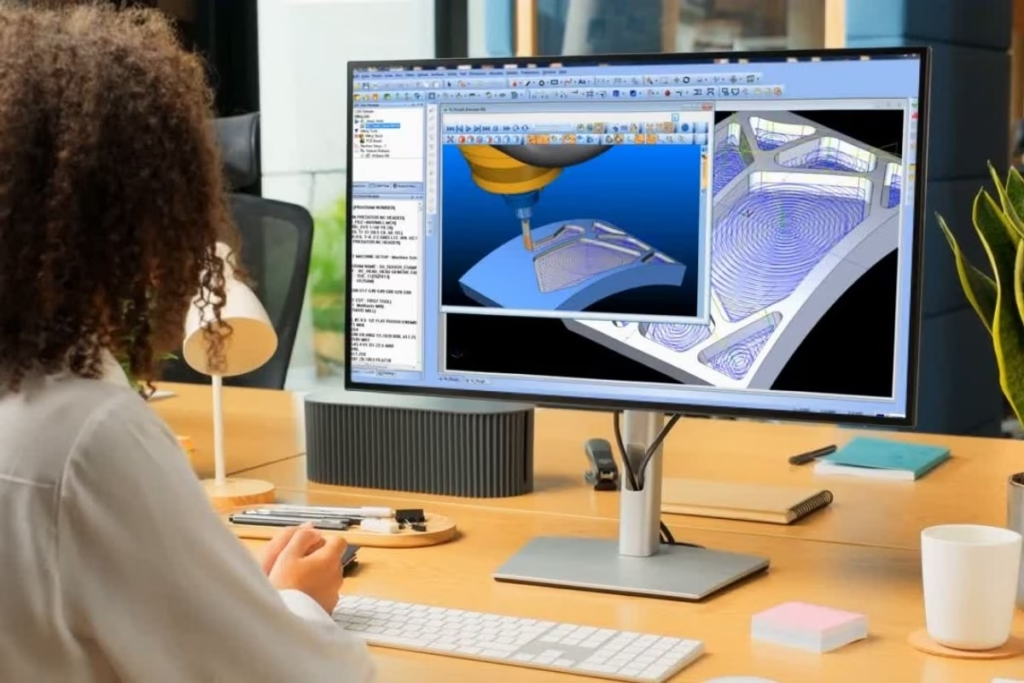

Our approach involves expert remote programming services where our team creates precise CNC machine instructions off-site. We utilize advanced CAD/CAM software to generate accurate toolpaths and G-code. We also provide detailed setup sheets, tooling information, and conduct collision checks to ensure programs are ready to run safely on your machines. If required we can offer simulation and support.

Custom CNC Programming Services

CNC Toolpath provides remote CNC programming services to ensure you get accurate, efficient, and machine-specific programming from skilled programmers. We are proficient in complex multi-axis CNC programming to meet diverse manufacturing requirements, from simple components to highly complex parts. We deliver production-ready programs tailored to specific requirements, such as precision tool paths, complex surface machining, or multi-axis optimization, to ensure smooth operations and minimal cycle times.

01

3-Axis CNC Programming

3-axis CNC programming involves controlling machine movement along three linear axes: X left right, Y front back, and Z up down. Our 3-axis programming service delivers efficient, accurate programs for simpler parts and lower production volumes. We optimize toolpaths even for 3-axis applications to improve efficiency and accuracy. This helps to minimize setup time and help maximize the potential of your 3-axis equipment for suitable projects by utilizing production-ready programs.

02

4-Axis CNC Programming

4-axis CNC programming adds a fourth rotational axis, typically the A axis, rotating along X to the three linear axes. This allows for machining of curved surfaces or angled features around that single rotational axis without manual repositioning. We provide expert 4-axis programming to handle parts requiring machining on multiple faces or featuring angled or curved details around one axis. Our programs reduce the need for multiple setups by increasing precision and improving efficiency, especially for high volume production requiring tight tolerances.

03

5-Axis CNC Programming

5-axis CNC programming involves two rotational axes in addition to the three linear axes, allowing simultaneous movement in five directions. Our specialized 5-axis programming services are ideal for complex shapes high volume production, and precision parts for industries like aerospace and medical. We handle the complex programming to deliver programs that enable single setup machining maximizing precision speed, and tool life while tackling intricate features. Our expertise ensures smooth uninterrupted code generation for demanding projects.

04

CNC Lathe Programming

In addition to milling, we offer expert CNC programming for lathe operations. Lathe machining involves rotating the workpiece while a cutting tool removes material to create cylindrical parts or features. The programming process is crucial for controlling tool paths, speeds, feeds, and transitions for different cuts like turning facing threading and grooving. Our CNC lathe programming services provide efficient and accurate programs specifically tailored for lathe machines. We deliver production-ready programs designed for high precision and superior surface finishes on turned components.

The CNC Toolpath Advantage

We bring years of experience in precision machining and programming across 3, 4, and 5-axis. Choosing CNC Toolpath means leveraging extensive knowledge and advanced techniques to optimize your machining process. We deliver production-ready programs tailored to specific requirements, such as precision tool paths, complex surface machining, or multi-axis optimization, to ensure smooth operations and minimal cycle times. We are committed to reducing cycle times, improving accuracy, and maximizing productivity through smart toolpath strategies.

Tools and Technology We Use

We utilize the most advanced CAD/CAM software to deliver top-notch results. Our tool set includes industry leading platforms like CATIA V5, Mastercam, SolidWorks, Fusion 360, PowerMill, and Inventor. For NC code validation, we specifically use Vericut to detect potential issues before machining begins. We also have expertise with post-processor development for various machine controllers such as Mazak, Fanuc, Siemens, Haas, Heidenhain, and Okuma.