How Remote CNC Programming Can Reduce Your Production Cost

In the fast-paced world of manufacturing, staying competitive requires continually seeking ways to enhance efficiency, minimize waste, and reduce costs. One of the most transformative innovations in recent years is the rise of remote CNC programming. This digital approach allows machinists and engineers to program CNC (Computer Numerical Control) machines virtually from anywhere. This shift not only enhances flexibility and productivity but also delivers significant cost savings across the production lifecycle.

What is Remote CNC Programming?

CNC machines are the backbone of modern manufacturing, responsible for producing a wide range of products, from automotive parts to aerospace components, with high precision. Traditionally, programming these machines required on-site presence, where engineers manually input G-code or use CAM (Computer-Aided Manufacturing) software directly connected to the machine.

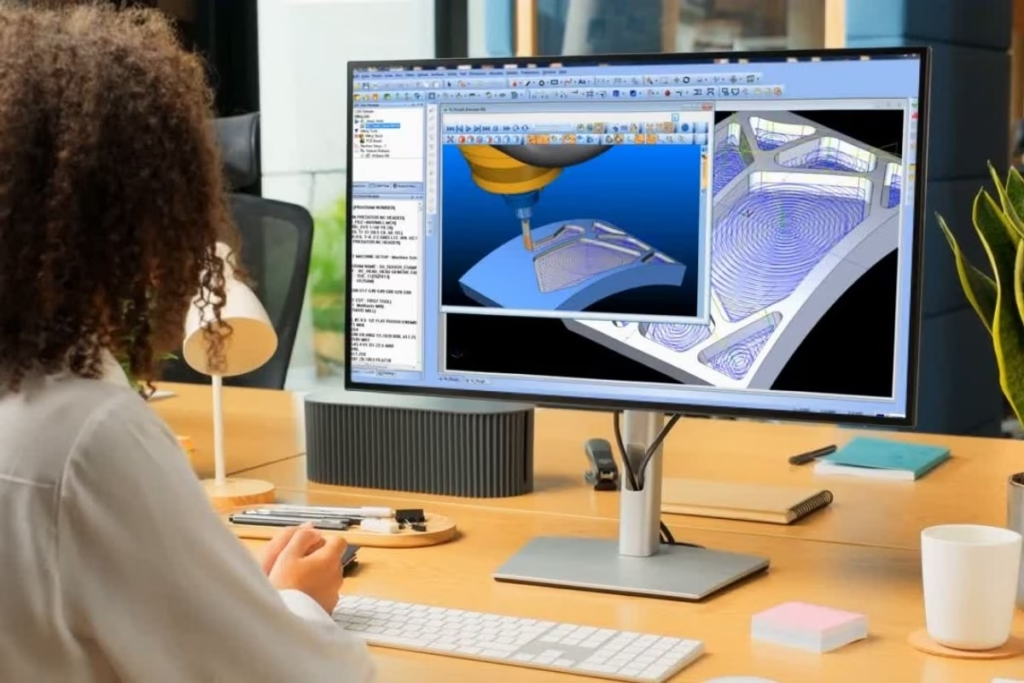

Remote CNC programming involves creating and optimizing CNC machine programs from an off-site location. Programmers use CAD/CDM software to generate code that directs machines in cutting, milling, or drilling operations. Programmers collaborate with engineers and machine operators to ensure precision and efficiency while troubleshooting any programming issues. Professionals can assist manufacturing processes while working from home or a remote office in this job.

The Cost Saving Benefits of Remote CNC Programming

Let’s explore the possible benefits of Remote CNC Programming:

1. Reduced Machine Downtime

One of the most immediate benefits of remote CNC programming is the reduction in machine downtime. In traditional setups, machines often sit idle while operators input or adjust programs. This non-productive time adds up quickly, especially in high-volume environments.

With remote programming, code can be prepared and tested off-site. Once ready, it’s uploaded to the machine, allowing production to resume almost immediately. This seamless transition minimizes idle time and maximizes machine utilization—a key factor in reducing operational costs.

2. Lower Labor Costs

Remote CNC programming enables companies to centralize their programming teams or outsource to specialized providers. This reduces the need for full-time, on-site programmers at every facility. Instead, a single team can support multiple locations, optimizing labor resources and cutting payroll expenses.

Additionally, remote access allows companies to tap into global talent pools. Skilled programmers from different regions can contribute without relocation costs or long-term contracts, offering flexibility and cost efficiency.

3. Faster Prototyping and Iteration

In modern manufacturing industries where speed-to-market is critical, Remote CNC programming accelerates the prototyping process. Engineers can quickly modify designs, simulate tool paths, and upload revised programs without waiting for machine availability.

Changes can be made remotely and simulations run instantly; design adjustments or engineering revisions are implemented much faster. This reduces waiting time between prototype versions and allows manufacturers to test multiple design iterations in a shorter timeframe.

This agility shortens development cycles, which allows manufacturers to respond faster to customer demands, market changes, or design improvements. The result is a more dynamic production environment with reduced lead times and lower development costs.

4. Enhanced Error Detection and Quality Control

Quality issues and programming errors can lead to wasted material, damaged tools, and lost production time.

Modern remote programming platforms often include advanced simulation and verification tools. These features allow programmers to detect potential issues—such as tool collisions, incorrect feeds and speeds, or inefficient paths—before the code reaches the machine.

By catching errors early, companies can avoid costly mistakes, reduce scrap rates, and minimize rework. Improved first-pass yield not only saves material and labor but also enhances customer satisfaction through consistent quality.

5. Improved Workflow and Collaboration

Remote CNC programming facilitates improved collaboration among design, engineering, and production teams. With shared access to CAD/CAM data, digital simulations, and project files, engineers and machinists can collaborate in real time.

This streamlined workflow reduces miscommunication, speeds up approvals, and ensures that the final machining program reflects the latest design intent. Efficient collaboration translates into fewer delays, smoother operations, and lower overhead costs.

6. 24/7 Programming Capabilities

With remote access, programming isn’t limited to regular working hours. Engineers can work across time zones or during off-hours, preparing programs while machines are running or idle.

This round-the-clock capability supports continuous production, especially in facilities operating multiple shifts. By decoupling programming from physical presence, manufacturers can maintain momentum and reduce scheduling bottlenecks.

7. Scalability and Flexibility

As businesses grow or take on new projects, Remote CNC programming offers scalable solutions. New machines, locations, or product lines can be supported without major infrastructure investments.

When workloads increase, additional remote programmers can be brought in immediately to handle the extra volume without the need for permanent staff. During slower periods, services can be scaled down, ensuring you only pay for what you need.

Whether expanding operations or handling seasonal demand, companies can scale their programming resources up or down as needed. This flexibility helps manufacturers stay efficient, control labor costs, and avoid production bottlenecks.

8. Optimized Tool Paths and Shorter Cycle Times

Expert remote programmers specialize in Cycle time reduction and tool path optimization. They fine-tune parameters such as feed rates, step overs, and cutting strategies to:

- Minimize air cutting

- Reduce tool wear

- Shorten machine time

- Extend tool life

These improvements can save minutes per part— a small number that adds up to thousands of dollars in savings across large production runs.

9. Real Cost Saving and Return on Investment

Manufacturers who adopt Remote CNC programming consistently report strong returns on investment. The observed benefits often include:

- 30–50% reduction in programming-related labor costs

- 10–20% faster machining cycles due to optimized tool path

- Reduced scrap and tool damage

- Higher machine uptime and better workflow efficiency

These savings lead to a leaner, more profitable production process without sacrificing precision or quality.

Conclusion

Remote CNC programming is further than a technological upgrade; it’s a strategic investment in effectiveness, flexibility, and bringing control. By minimizing time-out, optimizing labor, accelerating production, and perfecting quality, it empowers manufacturers to thrive in a competitive environment.

Whether you are a small job shop or a global enterprise, espousing remote CNC programming can transfigure your operations and deliver measurable savings. The future of manufacturing is connected, and remote programming is a crucial step toward smarter, slender products.

Discover more from CNC Toolpath

Subscribe to get the latest posts sent to your email.