NC Validation & CNC Toolpath Optimization Services

CNC Toolpath offers NC code validation using Vericut to detect potential issues like tool collisions before machining, proactively preventing costly mistakes. Our expertise also lies in optimizing CNC toolpaths to improve efficiency, accuracy, and cycle time. We utilize Vericut for NC code validation, and our CAD software packages include built-in toolpath optimization features.

About NC Validation & Toolpath Optimization

NC (Numerical Control) validation and toolpath optimization are crucial steps after generating CAM programs to ensure efficiency and prevent errors before machining begins. The validation step involves checking the machine code for potential issues, while optimization refines the toolpaths for maximum efficiency and quality.

CNC Toolpath Solutions

To prevent costly machining errors CNC Toolpath offer NC code validation using Vericut, which detects potential issues like tool collisions before actual machining. Our team optimizes CNC toolpaths to improve efficiency, accuracy, and cycle time. We ensure smoother motion, reduced machining time, and extended tool life while maintaining high precision. This refinement aims for maximum productivity and cost savings.

Comprehensive NC Validation and CNC Toolpath Optimization Services

CNC Toolpath acquires the best talent specializing in NC code validation using Vericut to detect potential issues like tool collisions before actual machining, proactively preventing costly mistakes. Our expertise also lies in optimizing CNC toolpaths to improve efficiency, accuracy, and cycle time. NC validation and CNC toolpath optimization are critical processes in modern manufacturing, specifically within CNC machining. These services aim to ensure that the programming instructions for CNC machines, known as G-code, accurately reflect the intended machining process and can be executed safely and efficiently.

NC Validation Services

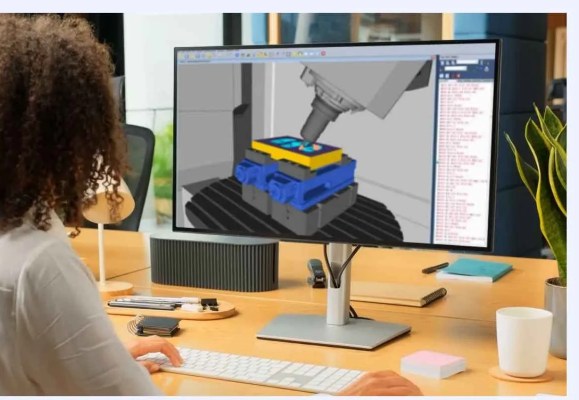

CNC Toolpath specialize in providing NC validation services to enhance precision efficiency and quality in machining operations. NC validation is a crucial step to prevent costly machining errors, as it uses NC validation software such as Vericut along with the G-code generated by CAM Computer Aided Manufacturing software to simulate the CNC machining process before it is run on the actual machine for error prevention and quality assurance.

1. Simulation: Using NC validation software such as Vericut, the CNC machining process is simulated based on the G-code generated by CAM software.

2. Collision Detection: The simulation helps identify potential collisions that could occur between the cutting tool the workpiece and machine components.

3. Error Detection: The process also detects other errors beyond collisions such as air cuts, unnecessary tool movements, not engaged with material or inefficient toolpath sequences.

4. Accuracy Verification: Validation ensures that the G-code accurately reflects the intended machining process

CNC Toolpath Optimization Services

We are offering CNC Toolpath optimization services mainly focuses on designing the most efficient and effective route for a cutting tool to follow during the machining process. CNC toolpath optimization focuses on refining the cutting tools movements to maximize efficiency accuracy and reduce machining time. We complements NC validation by not just checking for errors but actively seeking the best way for the tool to move through the material.

1. Reduced Machining Time: Optimizing toolpaths and eliminating inefficient movements significantly reduces the time needed to complete a part.

2. Improved Surface Finish: Minimized Tool Wear Optimization techniques aim to achieve a better surface finish and reduce wear on the cutting tools

3. Feed Rate and Speed Adjustment: Adjusting the feed rates how fast the tool moves and spindle speeds how fast the tool spins based on the specific material tool and operation is part of the optimization.

4. Toolpath Sequence Optimization: Refining the order of operations and tool movements reduces unnecessary travel and tool changes, further improving efficiency.

5. AI Based Optimization: Advanced techniques like genetic algorithms ant colony optimization and artificial neural networks can be employed to automate and enhance the optimization process.

Why CNC Toolpath for NC Validation and Optimization

We help extend tool life and maintain high precision, maximizing productivity and cost savings by refining toolpaths for smoother motion and reduced machining time. A significant pain point in CNC machining is the risk of costly errors like tool collisions or inefficient machine movement. Without rigorous validation and optimization, programs might lead to damaged tooling, scrapped parts, longer cycle times, and poor surface finishes.

Availability as a Service

CNC Toolpath provide these as part of a comprehensive suite of services to optimize CNC machining. Our NC Validation and CNC Toolpath Optimization are services offered remotely by our specialists. We leverage advanced CAD/CAM software and techniques to deliver efficient, accurate, and production ready programs tailored to specific project requirements from precision toolpaths to complex surface machining and multi-axis optimization. We also provide detailed setup sheets, tooling information, and collision checks to ensure the programs are ready for the clients machines.