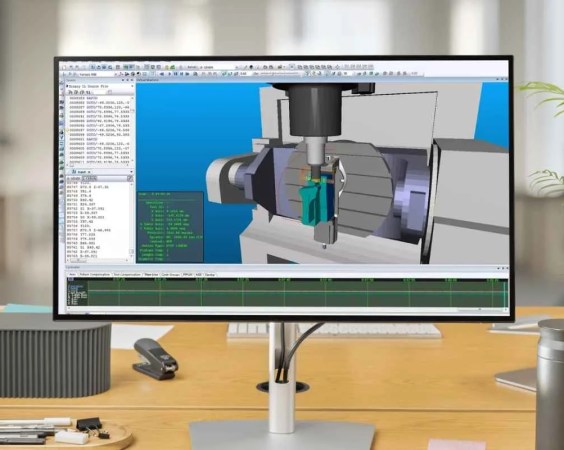

Post Processor Development & Customization Solutions

Post processors translate custom toolpaths generated by using CAM software into G-code for specific machines for optimal compatibility with the equipments. CNC Toolpath specializes in developing and customizing post processors for various CNC machines and controllers, including Mazak, Fanuc, Siemens, Haas, Heidenhain, and Okuma.

Custom Post Processor Development and Customization Services

The primary function of a post processor in CAM software is to translate the universal toolpath data, also known as CL data or Cutter Location data, generated by the CAM system into the specific dialect of G-code required by a particular CNC machine controller. Since different CNC machines and controllers, like Mazak, Fanuc, Siemens, Haas, Heidenhain, and Okuma, use different dialects of G-code, a specific post processor for each machine is absolutely necessary for correct interpretation and execution of machining instructions.

If you use a post processor that is not high-quality, you run the risk of errors, wasted time, damaged parts, potential machine destruction, and even danger to personnel. The process fundamentally involves the CAM software analyzing a CAD model to determine toolpaths outputting this as CL data. The post processor then takes this CL data and (guided by a post file or recipe) converts it into unique G-code for each specific machine.

CNC Toolpath Custom Post Processor Solutions

CNC Toolpath provides custom post processor development and customization solutions, specifically error-free code generation and seamless compatibility with a wide range of CNC machines and controllers, including major brands like Mazak, Fanuc, Siemens, Haas, Heidenhain, and Okuma.

We focus on delivering accurate and machine specific outputs for seamless production tailored to optimize toolpaths for 3-axis 4-axis and 5-axis machining. We offer solutions that are tailored to your specific requirements, whether you need a brand-new post processor, adjustments to an old one, or performance tweaking.

Advanced Post Processor Customization

#1 Integration of Probing Routines: Automating part zero touch offs and other probing operations

#2 Custom Cycles: Developing optimized drill cycles, deep hole drilling cycles, or other specialized machining patterns

#3 Tool Management: Enabling tool life tracking and management within G-code for specific machine features programming for capabilities like right angle heads or simulating tool compensation if the machine controller lacks native support

#4 Standardized Output: Ensuring G-code patterns comments for documentation and standard safety blocks across all programs

#5 Operational Enhancements: Modifying programs for tasks like moving the machine table to a convenient position at the end of a job #6 Flexible Machining Options: Setting up the post processor to easily handle variable setup options or enable partial machining runs

#7 Integration of Setup Information: Potentially automating the generation of setup sheets along with the program

Get custom post processor development, customization and G-code for specific CNC machines

Post Processor Customization Services

CNC Toolpath offers comprehensive services for CNC machine solutions such as toolpath generation, G-code, post processor, custom CNC programming, etc.

We provide expertise across the entire workflow, including CNC Programming for 3-axis, 4-axis and 5-axis Milling and Lathe Machines, 3D Modeling, CAD designing, NC Validation, CNC Toolpath Optimization, CNC Engraving, Artistic Machining, and CMM Programming and Inspection Services.

We offer this comprehensive, integrated approach that ensures that every aspect of your digital manufacturing process is optimized for precision and efficiency.

CNC Toolpath for Post Processor Services

For your post processor development and customization needs, choosing CNC Toolpath has big benefits that will directly improve the accuracy, efficiency, and profitability of your machining operations. We ensure the G-code generated by the CAM software is perfectly compatible with your specific CNC machine and controller.

This prevents communication issues and facilitates seamless production. We support machining of highly complex geometries and multisite parts efficiently in a single setup, which is a key advantage of 4-axis and 5-axis machining. Let us partner with you to develop or customize your post processors to maximize precision and efficiency in your machine shop.